I'll try and keep things as simple as possible and no doubt the cognoscenti will pitch in if they spot any errors.

All stationary diesel regulators have 3 basic adjustments:

1) Idle speed

2) max free-load speed

3) Max fuel inject volume - sometimes referred to as 'rack' or 'rack max'

So firstly you need to realise that the cable control you connect to the twist grip is not a 'throttle', more like a ships telegraph whereby you request certain revolutions from the engine room. You can feel this when you ride as holding the twinstgrip in a fixed position over an undulating road will cause the motor to 'fuel up' on the inclines and shut off on the downhill bits - this can really catch you out when you use bigger engines especially on roundabouts.

So idle speed - seems pretty obvious although on some fittings they rely on the control cable tension to set this - not good on a motorcycle, hence the additional fittings on Henry Price's Yanma clone installations. A word of warning, do not set this too low, for a single they usually need 1200 rpm as a minimum. Whatever you do don't let the motor start 8 stroking with a heavy banging ignition as this can destroy a crank or balancer shaft in short order. Essentially what is happening is the governor senses the engine speed is too low and puts the injector to full so as to prevent a stall. This leads to huge accelerations of the flywheel and ancillaries such as balancer shafts and their drive gears - not good.

Max free load speed - pretty much as the name suggests and easy enough to set of you have a tacho. Be aware of 'regulator droop', this causes the max speed to slow as the motor gets hot so most workshop manuals suggest setting it 1500 rpm higher than the 3600 setting to allow for this phenomenon. Don't be silly at try and get your single to rev to 4000+ it will only destroy itself and possibly take your head/leg/arm off when it let's go.

Max Fuel Inject Volume - this is commonly the most misunderstood control as some think of it as a key to endless power. It will usually be wire locked if new and will have a spring loaded tip. This controls the maximum volume of fuel the injector can deliver; nothing else. Now for the controversial bit.....If you fit a small diesel to a motorcycle you should consider turning this DOWN; whoa! stop shouting and I'll explain why.

In the normal engines fitting be it a concrete mixer, pressure washer et all, firstly the requirement was for 7hp then they would fit a 10hp motor as suddenly chucking a few spadefulls of wet sand into the bucket will suddenly increase the load and the motor needs to cope. Under this circumstance the motor will OVERFUEL briefly to gain the absolute maximum immediate response (chucking in 50% extra fuel may gain you 10% over power but a lot of unburned black smoke).

When your charging down the motorway on your Yanclone/Hatz/Lombardini and pulling the wire hard against the stop you can get into the over- fuel condition for long periods of time. When this happens not only will your fuel consumption go through the roof but cylinder temperatures will rise to possibly damaging/seizure territory.

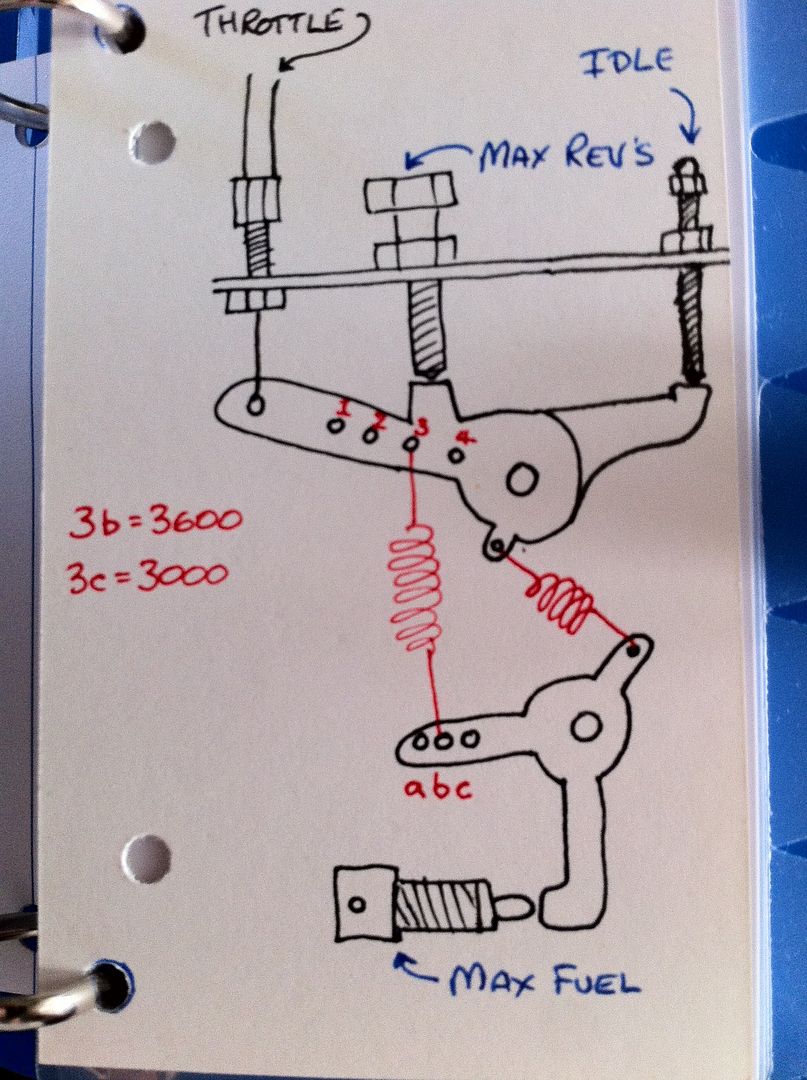

Here's my rendition of a typical Yanmar clone dual spring setup:

So you have 2 rotating arms connected by 2 springs, inside the casings will be the governor speed control and the arm that connects to the injection pump.

As you can see the max inject control is set directly on the lower pivot whereas the max speed and idle speed are set on the upper, so no matter how hard you pull on the control you cannot bypass the max inject function, also the controls INFLUENCE the lower control but do not INSIST, as they are only connected by the spring tensions. If you experiment and bypass the upper control function and attach a cable directly to the lower pivot you will find out just how hard the governor will pull back against your wrist.

I hope this helps.

Feel free to pitch in.